Tasks and Trackers

Tasks & Time Trackers

FabStation includes Time Trackers and Production Tasks. These tools help you document the work completed, maintain accountability, and support quality control throughout production.

This article explains how both features work and how your team can use them on the shop floor.

Time Trackers

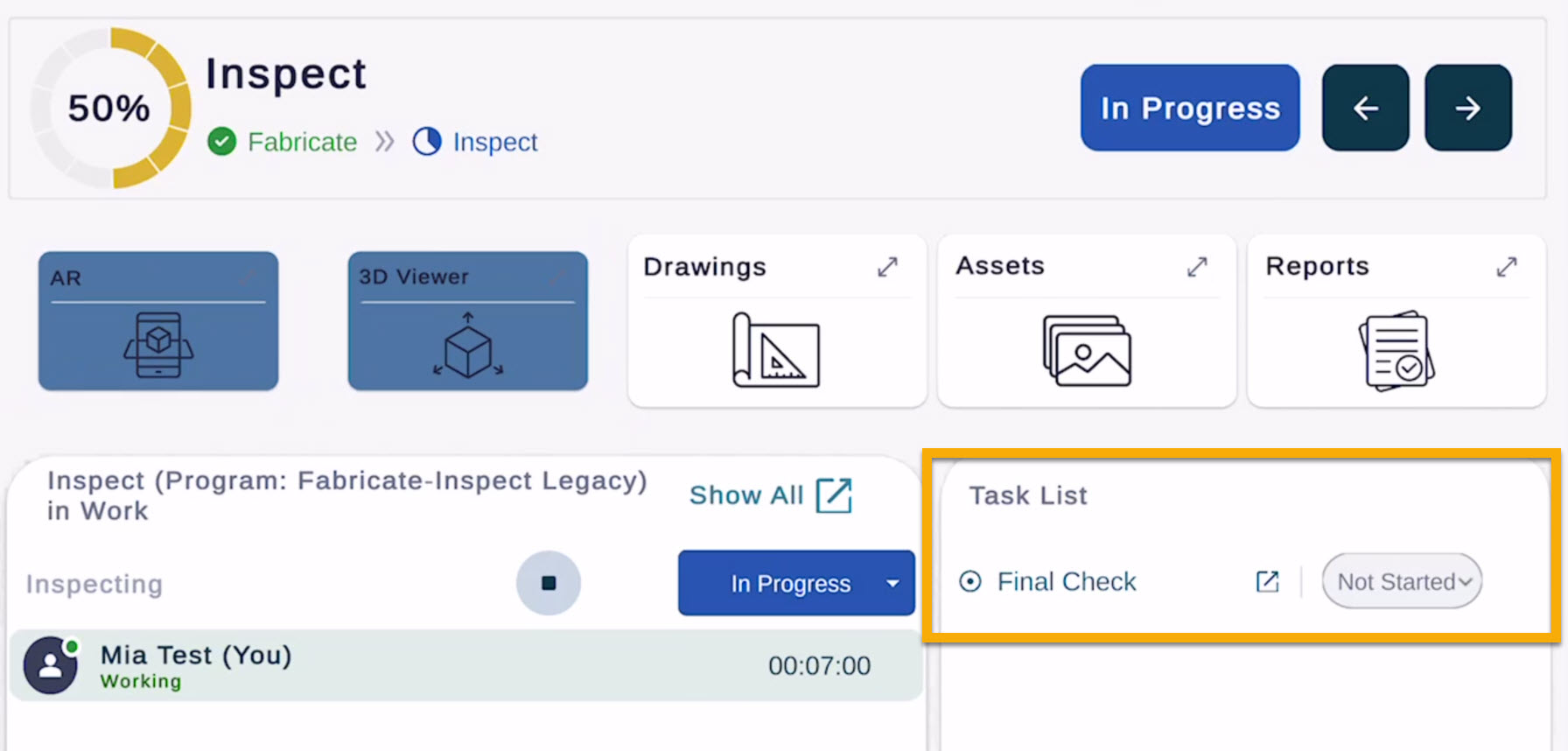

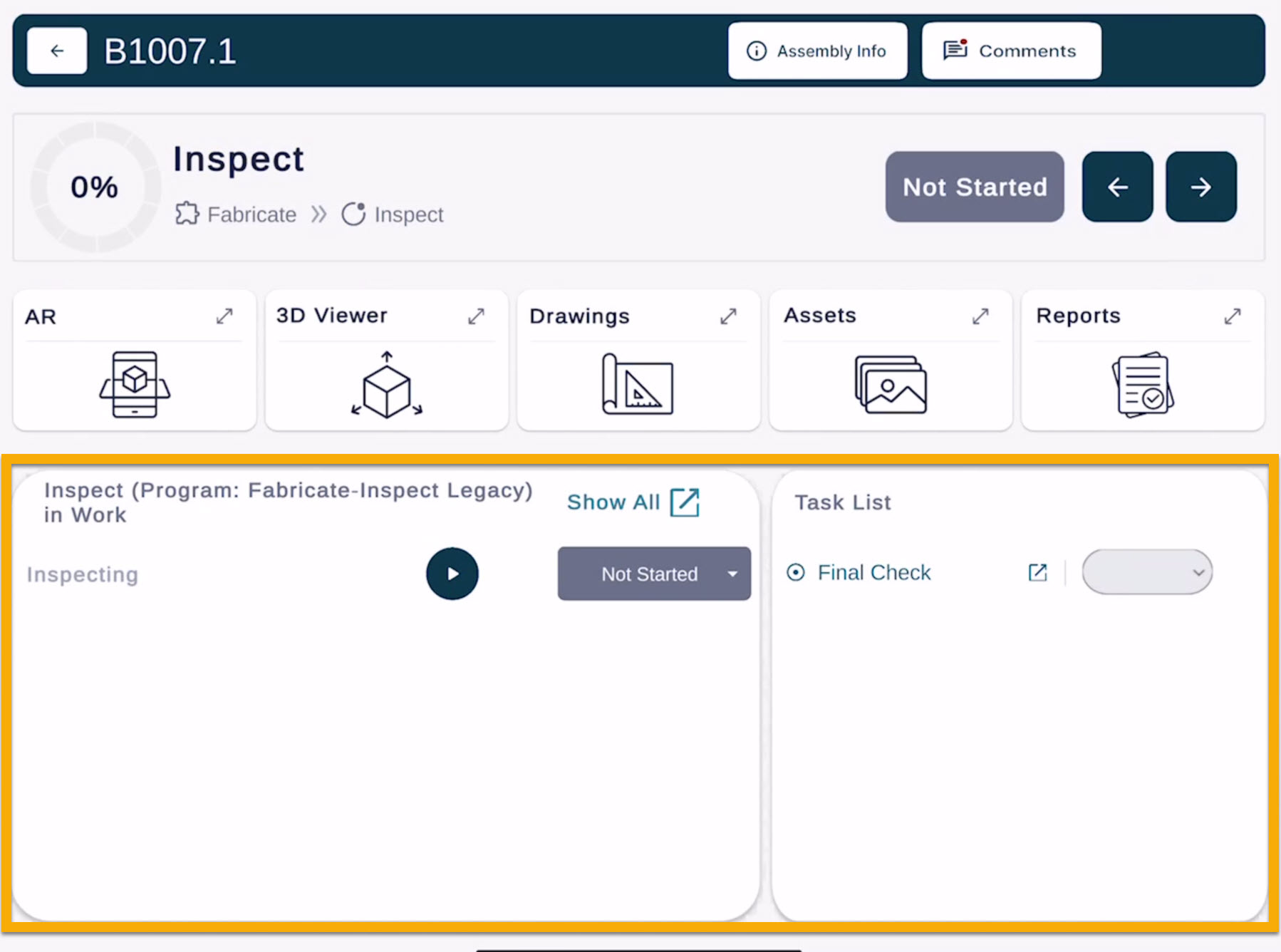

Most stages in the FabStation production workflow includes a Time Tracker. Time Trackers allow users to log how long they spent working on a specific stage of an assembly.

How Time Tracking Works

First, log in to your FabStation account on your device. Select the assembly you are working on. Tap the current stage (e.g., Assembly, Welding, Surface Preparation).

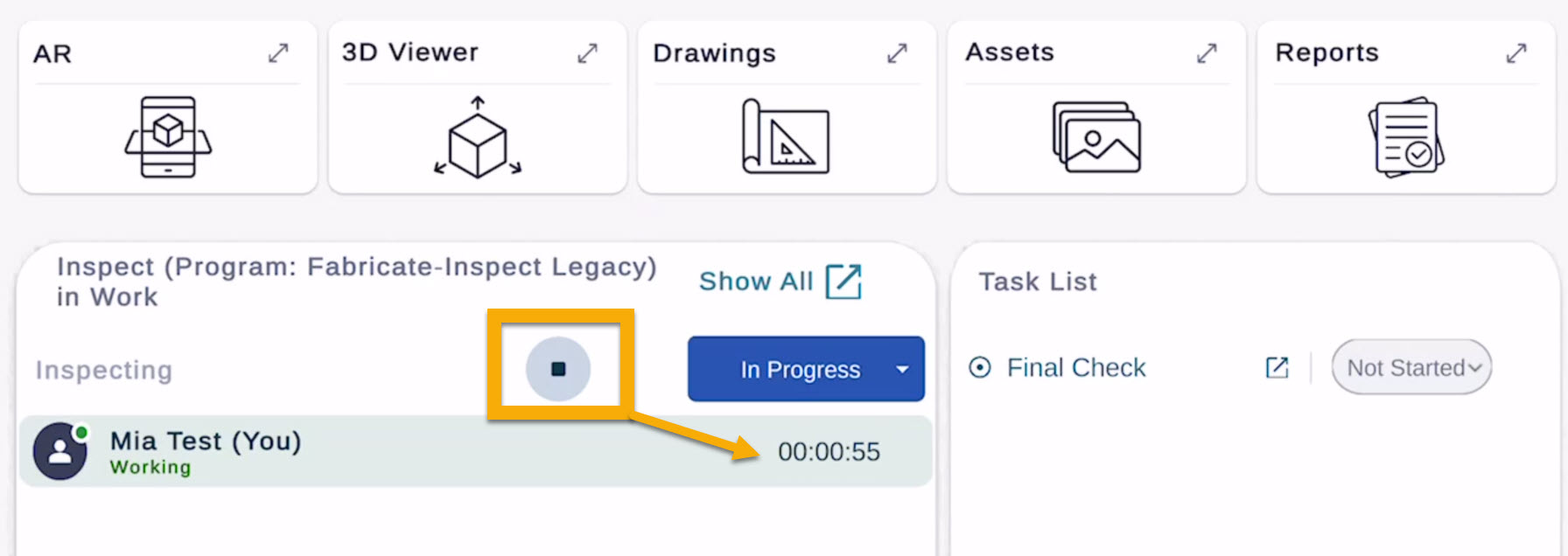

Press Start on the Time Tracker to begin logging time.

If you need to step away, press Pause.

When the work is complete:

Press Stop, or

Change the stage to Complete, which will also close the tracker.

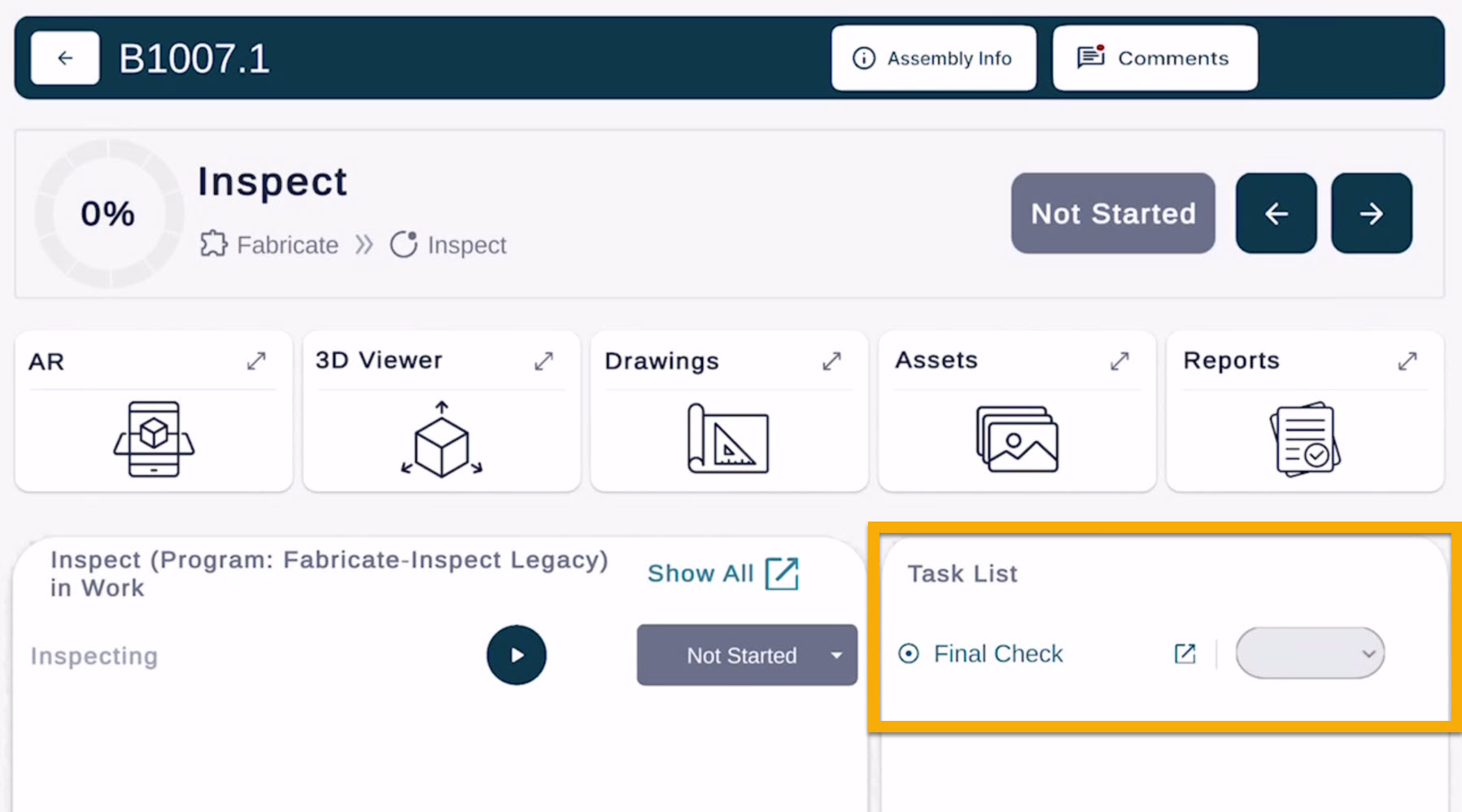

It is not possible to mark a stage COMPLETE if there are any outstanding tasks.

What Time Trackers Provide

Accurate time logging per assembly and stage

Better visibility into workflow status across departments

Data for reporting and production planning

Tasks

Each stage may also include Tasks that guide work and assist in quality verification.

Tasks help ensure consistency and help connect AR, 3D Viewer, and documentation back to each assembly.

Learn more about tasks offered within FabStation:

- Checklist

- Reports

- Assets

1. Task: Part Checklist

Quick Pass Part Checklist

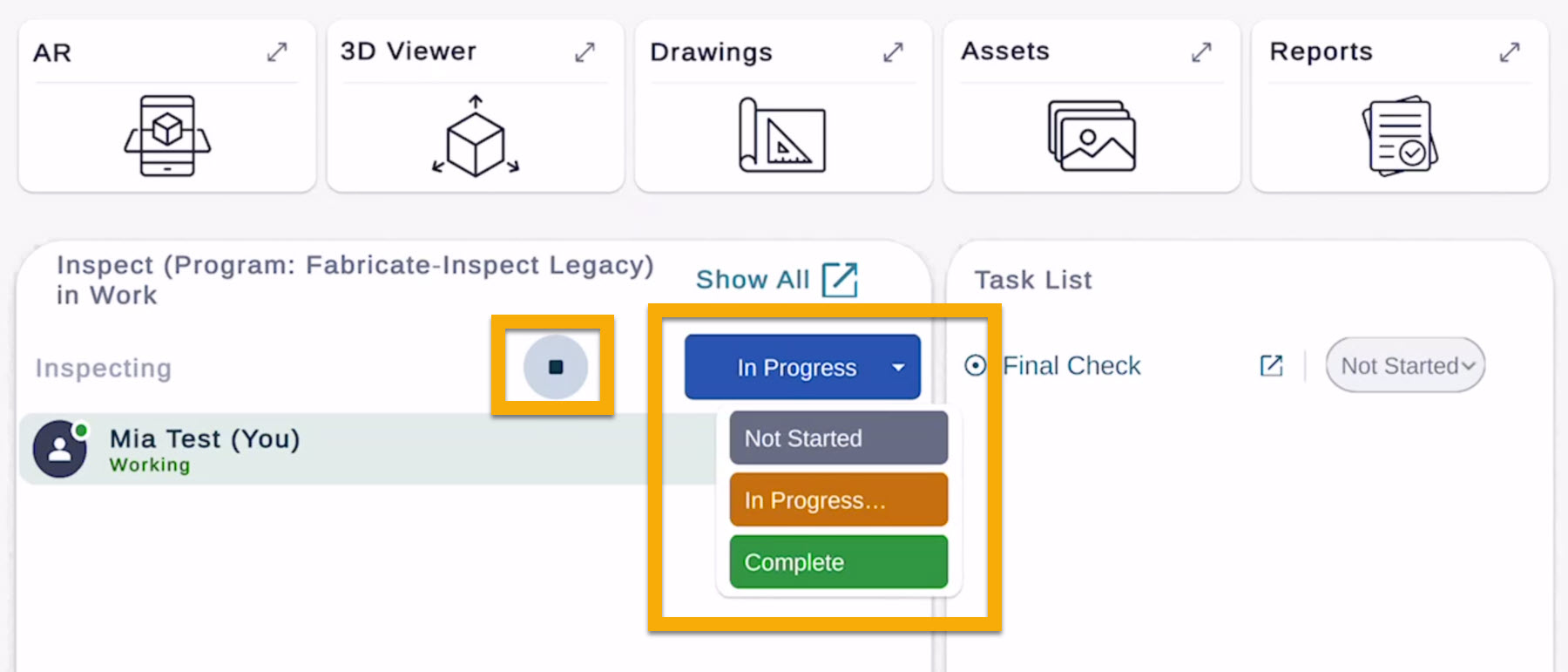

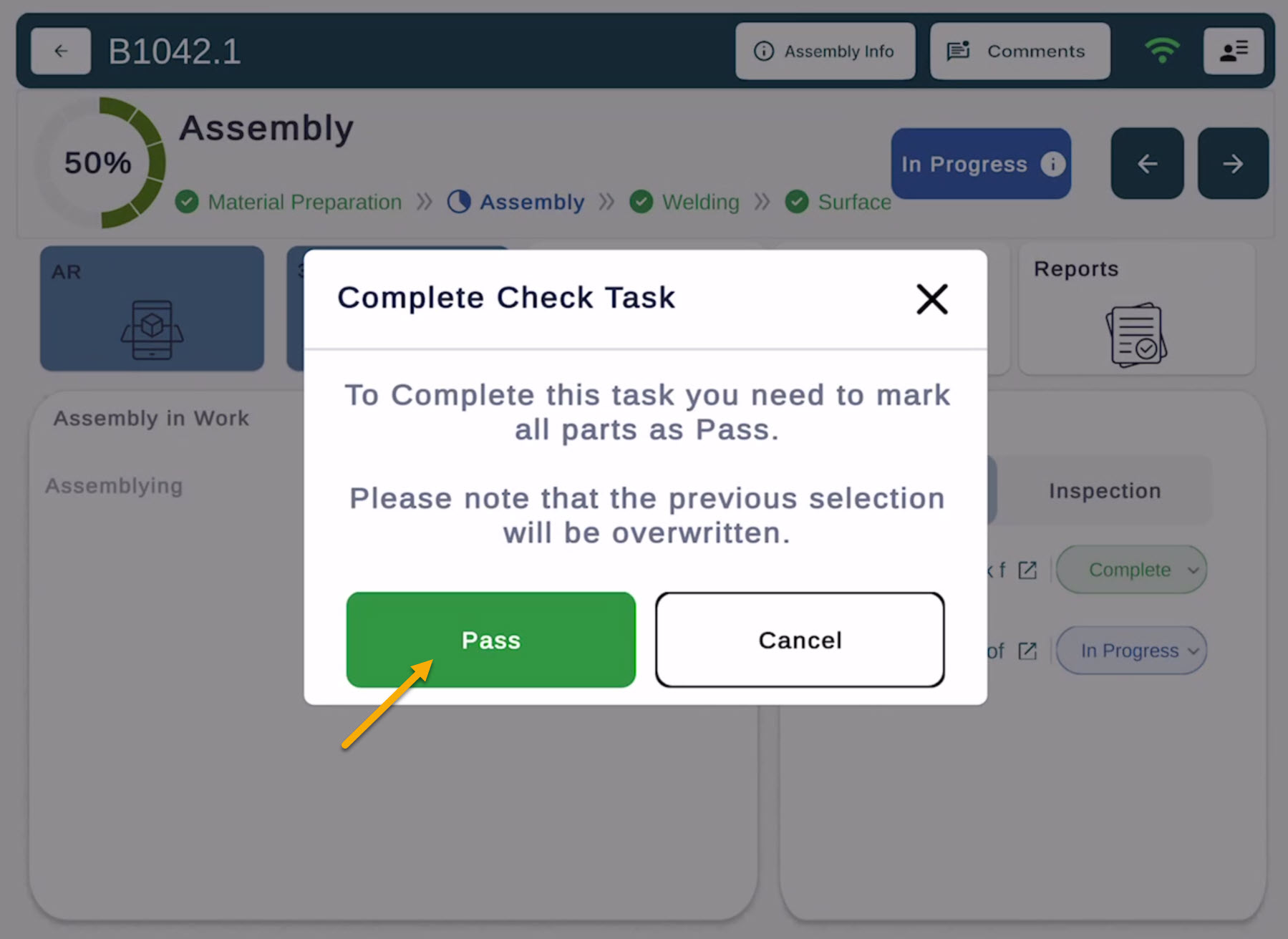

If you tap on the Not Started drop down next to a checklist task, and Change it to Complete, you will be prompted to Pass all parts automatically.

Learn more about using part checklists in the Part Checklist article.

2. Task: Reports

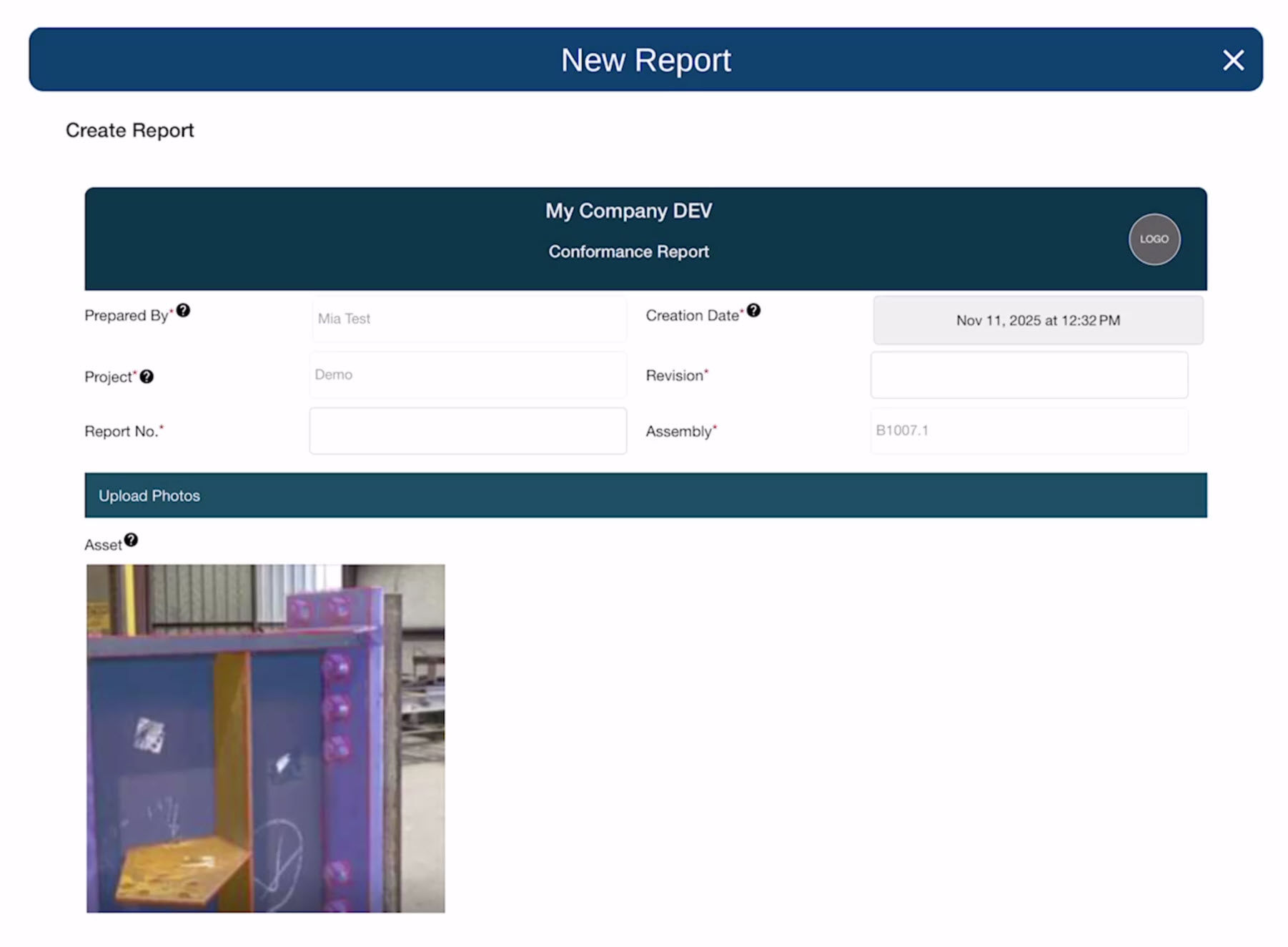

Some stages may include reporting tasks. These are used when issues need to be documented.

For example, you may submit a Non-Conformance Report (NCR) or a Conformance Report (CR) or a Weld Report if something needs to be addressed or confirmed before the assembly can continue.

Learn more about reports here.

3. Task: Assets

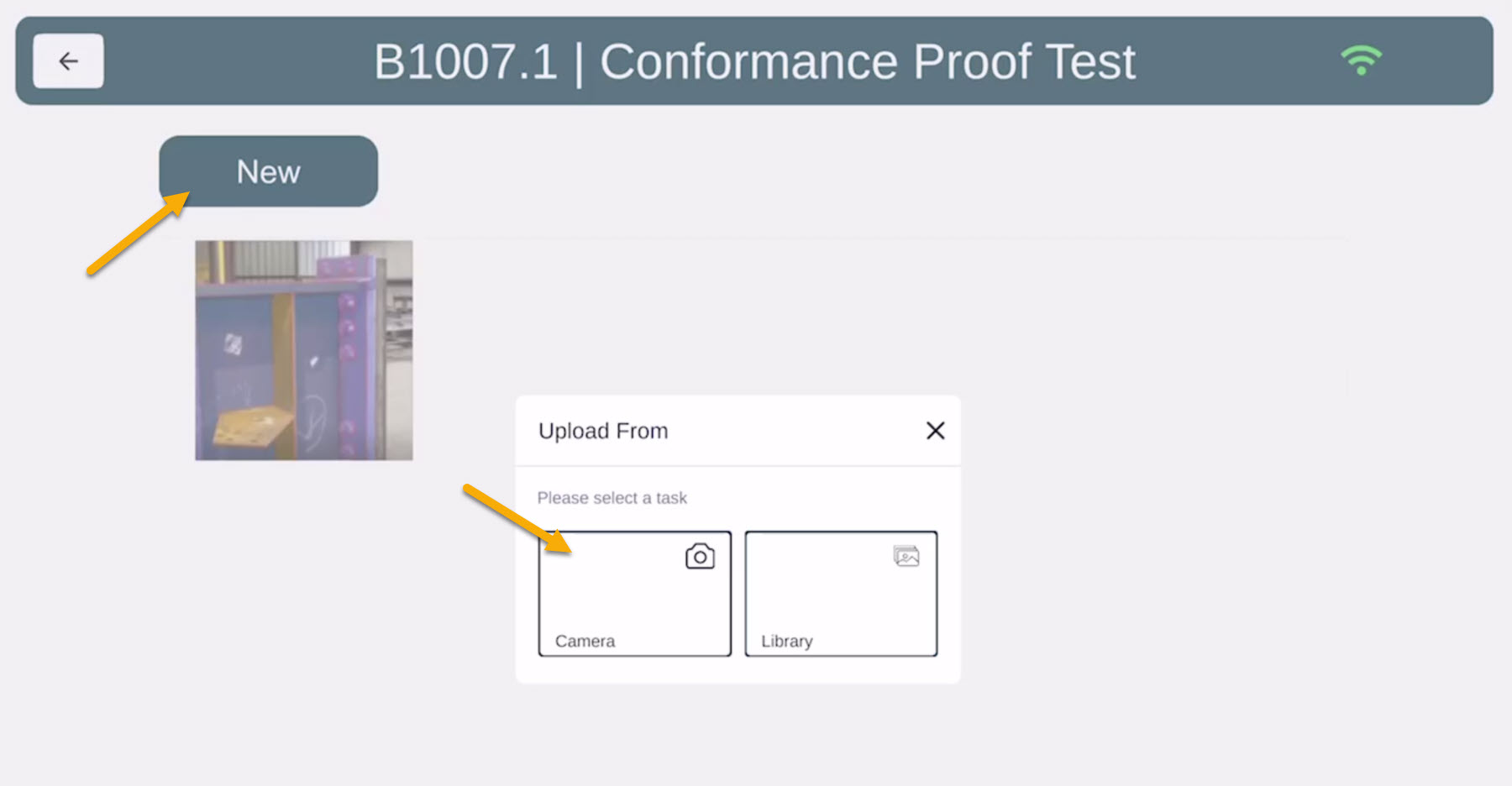

Some tasks may require you to take a photo of your assembly.

You can take photos directly within the app and add markups if needed. These photos are automatically stored under the assembly’s Assets, so they remain linked to the correct project and stage.

Learn more about assets here.

Why Tasks Matter

Ensures that important verification steps are not skipped

Keeps documentation organized and linked directly to the assembly

Supports communication between fabrication, QC, and shipping team