When structural steel fabricators come together, the topic of doing more with less always comes up. It is hard to find fitters, and shops are looking for a way to make the fitting exercise faster without compromising quality.

There are many new products on the market to try and address this need. Whether it is visual laser layout, CNC scribing, using laser, plasma, or drill bit, or augmented reality, each solution is unique and provides different value. There are many questions about which is the best solution for your shop.

Considerations

Many shops don’t have the space for “one more piece of equipment” and the new layout machine gets shoehorned into whatever space is available. In these times of Lean and 6-sigma manufacturing, it can lead to an inefficient workflow with less than desired results. The solution chosen for your shop must either fit into existing workflows, or modify the workflow to improve efficiency.

Many equipment manufacturers tout the benefits of “replacing x fitters” with this latest equipment; the reality is shops still need the same number of employees. The machine still needs an operator, someone has to create the program file, and unless you go full automation… fitters will always be required to perform the work. If you do decide to downsize your employee count, which fitters do you keep? The ones with the most skill, but close to retirement? This will lead to the same skill shortage a few years down the road.

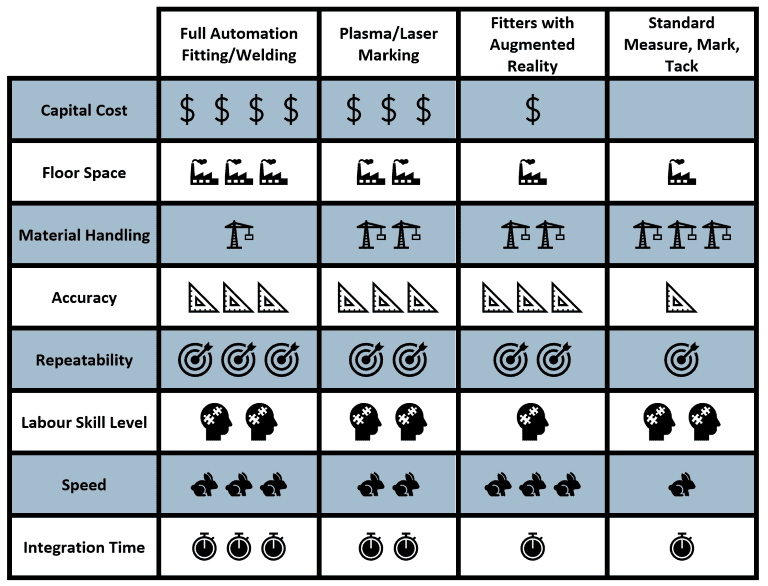

Capital cost is another factor to consider when researching options. As mentioned, every solution and provider has a calculation to give approximate cost savings. It is recommended to dig into the numbers yourself to provide an evaluation on your shop and potential savings; are the numbers realistic? If you are anticipating needing less fitters, will that actually be the case? Or will you simply be searching for skilled workers with a different area of expertise? What if this new piece of equipment fails to meet the expected savings? Is there a guarantee from the manufacturer?

There are several factors to compare when deciding which system to choose. The table below gives an overview of the main factors to consider:

A better way

A better method to make fabrication quicker and more efficient is to give the fitters new tools for layout. If the fitter can quickly interpret the design and accurately place the small parts on the assembly, they can then tack and send the assembly for welding as quickly as possible. It is even possible to upskill your welders to fit the simple beams themselves.

Introducing technology to the more experienced fitters can be difficult. However, if management demonstrates a commitment to introducing innovative new tools and not downsizing the workforce, they will be more willing to embrace the technology.

Additionally, hiring less skilled workers that are more technologically savvy can lead to a larger pool to draw from. Training workers to grow with your business and utilizing technology will provide more value in the long run.