Today’s modern steel shop is forced to do more with less. Less personnel, less space, less production time, and less tolerance for error. One very effective method of doing more with less is through digitalization.

However, getting your shop to be more productive through digitalization is a major project, not a “quick fix”. As with any major project, it starts with a well thought out plan and needs to be executed with the same amount of care and attention as any other major project that you undertake at your shop. Some things to consider:

What is the desired outcome?

- There needs to be a measurement of success. Whether its cost savings, time savings (velocity) or reducing errors/re-work

What is your budget?

- Every project needs an honest budget. Take the time to do research and have a realistic budget. If your friendly shop down the road spent “x” on their upgrade, don’t assume you can do it cheaper.

Do you have a timeline?

- Depending on the scope of the project there may be a different timeline. Do you want to start immediately? Is this something that needs to be planned out over the next year or within the next 2 years?

Do you have the knowledge and resources to execute the project?

- Change does not happen on its own. You will need to devote resources to be the champion. Who will that person be? Can you spare them for the duration of the project? Do you need to hire outside expertise? How long will integration take?

Adding automation without a solid plan could create new bottlenecks in other areas of the shop. As with any manufacturing process, the overall velocity is only as fast as the slowest process.

Fortunately, there is a simple, yet impactful place to start the digital journey. Working with your Detailing Partner before the project is awarded you can start going digital immediately.

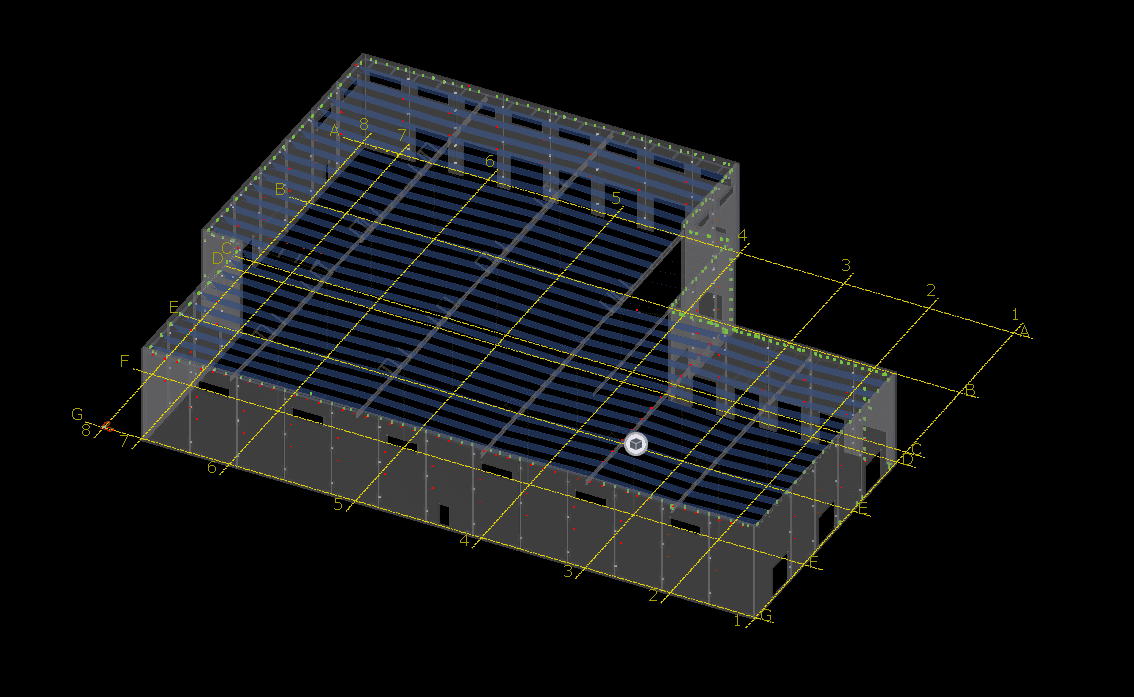

The digital journey of a project starts with the A&E, but intersects with the fabricator at the Detailing stage. If you can engage a trusted Detailing partner early in the process, the digital assets can easily flow down to the shop floor. The files required for the MRP software, CNC machine, beam line, AR/MR software and PDF drawings all come from the detailed model. By engaging the Detailer in the bid and estimating stage, they can create an estimation model (“estimodel”) that will increase efficiency before the job is even awarded to your shop.

The estimodel is a proforma design that allows the estimator to automate the take-off stage of the bidding process. Many shops still do this in-house, reviewing paper drawings with a highlighter, going cross-eyed after many hours of pouring through drawings. This time could be better spent on digging into the details of the project, with the 3D model as a reference, to discover the hidden risks they may have missed otherwise.

It may seem counterintuitive to go to your detailer at the bid stage, but the quality of the model and the conversion to a full design (once the job is awarded) leads to greater efficiency. The effort to create these models is not lost, as the estimodel is used for the basis of the detailed design.

Contact your Detailer and ask them about estimodeling your next project. If you need some recommendations, consult the AISC Member directory to find a Detailer in your area.

Next month we will cover how to manage these digital assets so you don’t get lost in the revisions!